The Challenges of Air Conditioning and Ventilating Basements

Basements represent a unique challenge when it comes to air conditioning and ventilation, particularly the latter. They can be further complicated if these areas are to have high student occupancy rates.

This was the challenge we faced on a recent project at a college in Oxford. Their unused basement was to be converted into three new classrooms and a student breakout area. The total occupancy was for 80 students at any one time. Initially we were ask to cost a proposal designed by a professional M&E consultant. The cost of this was such that the whole project became unviable. It was at this point Air Intelligence offered to design a solution more fitting with the budget available.

The Challenges:

Volume of ventilation: The whole nature of classrooms is that they have high occupancy rates for the size of the space. The basic requirement for classroom spaces is for the ventilation to provide 8 litres of fresh for each person, every second of the day. This means a classroom of 20 people needs 576 m3/hr of fresh air. Across all four new rooms, this was over 2300m3/hr.

Ducting Routes: The second complication in ventilating a basement is finding a route through which ductwork can be installed. Since the ventilation unit would be roof mounted, we needed to find a route from here to where the air is needed. Fortunately, we were able to adapt and enlarge an existing riser cupboard.

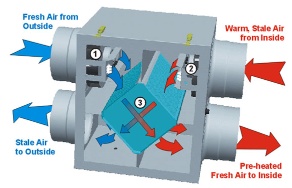

Ventilation capacity: Next up was finding a ventilation unit that was powerful enough to provide the required air flow, but small enough to fit in the small roof space we had available. This is where Barkell, based in Co. Durham stepped in. Their Therm-x range of air handling units come in a range of sizes and configurations. Compared to the alternatives, it was the only system that could provide the duty, but be small enough to fit the available space. At 500kg, it required a telehandler type forklift to get it onto the ground floor roof, but after that, it was relatively easy to install.

Fire Safety Regulations: Being a basement, meeting fire and smoke safety regulations was our next challenge. We had to ensure the system:

- was linked to the fire alarm such that it would automatically shut down in the event of a fire. Its very important ventilation systems do not feed fires with fresh air.

- Smoke sensors in the ductwork that linked to the fire alarm that ensured the ventilation system automatically shuts down in the event of a fire inside the air handling unit.

- The air handling unit can be made to operate in ‘exhaust only’ mode to draw out smoke from the basement after a fire.

- Fire and smoke dampers between spaces to prevent transfer of smoke/fire.

Limited ceiling height: The next challenge was finding air conditioning units that could fit above the very limited space above the new suspended ceiling. In the end, we went for Panasonic 10kW PACi ducted units. This are only 250mm high, which is probably to lowest currently on the market. Not only that, they also can have a pipe run of up to 50m.